Dimensional Calibration.

Guaranteed in 5 working days or less – simply a better dimensional calibration service

We’re open with all collection and drop off options operating as usual.

Guaranteed in 5 working days or less – simply a better dimensional calibration service

We offer ISO standard dimensional calibrations on tools and equipment

We’ll supply a calibration certificate pdf with all ISO standard dimensional calibrations

Our 5 day lead time for dimensional calibration is inclusive of collection and return, minimising disruption to your business while maximising uptime

We only use state-of-the-art dimensional calibration equipment, operated by highly skilled technicians

Keeping your dimensional devices calibrated and accurate on your schedule.

Regular calibration of dimensional tools keeps your measurements accurate during use, guaranteeing your readings are exactly as they should be.

At our dimensional calibration laboratory in Birmingham, or on-site at your business, our team of experienced technicians calibrate the following types of dimensional equipment to British standards:

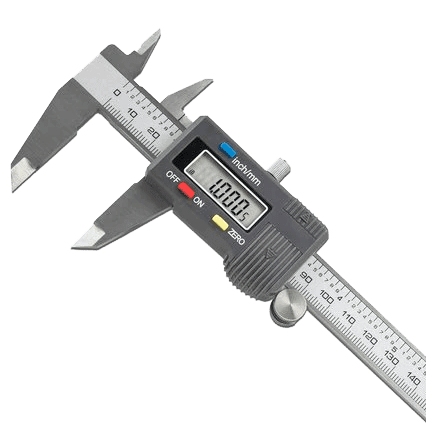

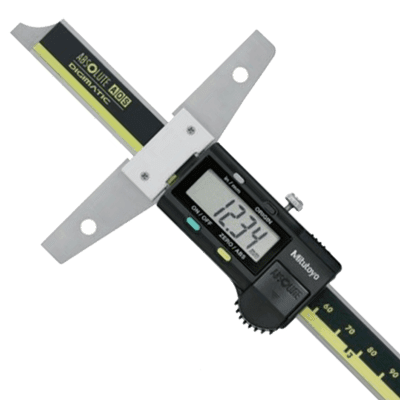

Callipers are one of the most common hand tools used within manufacturing. Due to their precision & accuracy it’s important run a dimensional calibration on your callipers at least once a year to ensure they are delivering the correct results. We calibrate a full range of callipers, including:

Micrometers are used to measure thickness, diameters, and depth of slots with small distances. We recommend calibrating your micrometer at least once per year to guarantee the precise readings the tool must generate to meet safety and compliance standards.

Dimensional gauges are essential for measuring many different types of components and products manufactured across many industries. Dimensional gauges are often used on a daily basis and their results are depended upon to ensure quality and safety. Due to the frequency of use and demands placed on these tools, we highly recommend that they are calibrated at least on an annual basis.

Quantity discounts available when booking in 10 or more electrical items for calibration.

If you don’t require a 5 day turnaround for your electrical items, you can qualify for further discounts depending on how long you can wait for your items to be calibrated.

Dimensional equipment – including items such as micrometers, calipers, ring gauges, plug gauges, digital indicators, levels and gauge blocks – is used in some way in nearly every manufacturing process.

The measurements taken from dimensional equipment play an important role in monitoring any deviations within manufacturing processes. Therefore, it’s crucial your dimensional equipment is regularly calibrated to ensure it remains delivering accurate results.

Temperature is the main consideration for any laboratory performing dimensional equipment calibrations – not only of the equipment or parts to be measured – but also the temperature of the measuring equipment standards and the temperature of the calibration environment.

To ensure the environment is consistent, measurements are taken in a 20°C temperature-controlled room or by making temperature corrections if the measurements are taken at a different temperature.

Further steps to ensure the temperature of dimensional equipment is kept consistent during calibration include wearing gloves to prevent heat transferring from hands to the item, and allowing the item to acclimatise to the temperature within the laboratory before the calibration takes place.

Gauge blocks are the master dimensional standard used in most calibration laboratories. Gauge blocks are sets of individual blocks where two opposing faces have been precisely ground flat and parallel so that the faces are an exact distance apart, giving a length accuracy of as low as a few micro-inches.

Mitutoyo device calibration

Mahr device calibration

Moore & Wright device calibration

Also: RS Pro, Kennedy, Starrett and more…

If your dimensional device cannot be calibrated or is uneconomical to repair, we will contact you straight away and offer a branded like-for-like replacement. We will supply the replacement device calibrated to your original order requirements.

With hundreds of pieces of equipment on-site requiring calibrations, it can be a struggle to keep on top of the deadlines, documentation and suppliers involved in the process. We have the solution…

We can calibrate much more than the items we’ve listed above, including electrical, pressure, temperature, weight and mass, so please drop us a message with your requirements and we’ll provide you with a quick, no-obligation quote.