Preventing Hand Arm Vibration Syndrome

Regular testing prevents claims

Hand Arm Vibration Syndrome (HAVS) is a serious and permanent condition where the nerves, blood vessels, and joints of the hand, wrist, and arm become damaged from working with vibrating hand-held or hand-guided power tools at work.

The Control of Vibration at Work Regulations 2005 were introduced to better protect workers from over-exposure to vibration at work, and subsequent legislative requirements were added in 2016.

Although Health and Safety Managers understand that they are under a legal obligation to protect their teams, very few maintain a preventative program of testing to ensure all tools are maintained to a standard that prevents increased vibration.

Before we explore the essential role of regular testing in preventing HAVS, let’s review the basics.

What is hand arm vibration syndrome?

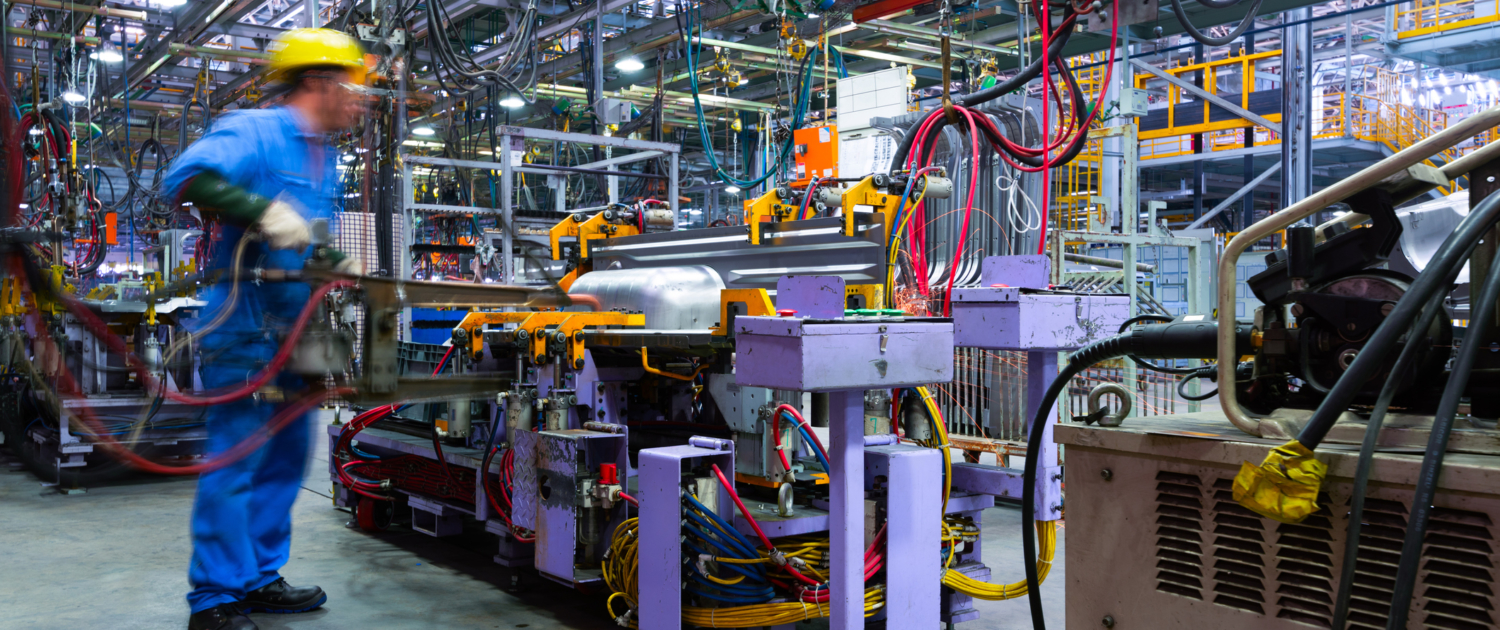

HAVS, also known as ‘white finger’, is a serious and disabling disorder of the blood supply to the fingers and hand. The Health and Safety Executive for the UK estimate that nearly two million people are at risk, in industries such as manufacturing, construction, forestry, and commercial landscaping.

Early signs and symptoms include tingling and numbness in the fingers which can be severe enough to disturb sleep, loss of sensation in the fingers which makes it hard to feel things, and even loss of strength in the hand.

The condition is termed ‘white finger’ because fingers periodically turn white (blanching) and then become red and painful on recovery. This is usually more prominent in cold weather and starts just at the tips of the fingers – affecting more of the fingers as time goes by.

HAVS compensation claims

Despite laws passed in 2016 to protect workers from the effects of over-exposure to vibration at work, there are still a considerable number of HAVS compensation claims each year.

Existing and retired employees are free to make a compensation claim against your business if they feel they are suffering from hand arm vibration syndrome. Compensation can range from £2,500-£6,500 for minor HAVS if symptoms do not interfere with day-to-day life and up to £25,220-£30,630 for a person with severe HAVS in both limbs*.

HAVS prevention best practice

Hand-held and hand-guided equipment such as power tools, drills, strimmers, and mowers should all be tested regularly to ensure they are working correctly. Vibrations occur in these types of tools when the tool wears and rotating parts become out of balance, or when it becomes blunt. This means that correctly maintained tools are far less likely to cause HAVS.

The important thing to remember, is that this applies to all hand-held and hand-guided tools. Despite this, many businesses still only take a small cross-section sample of assets for random testing to ensure compliance under The Control of Vibration at Work Regulations 2005. This is not best practice, and should a claim be brought against you, your paper trail will prove you negligent of sufficiently protecting your employees by not testing every tool.

Best practice HAVS testing should happen annually for each tool. This ‘all tools, every year’ approach will give you the certification and paper trail required for audits and claims purposes, ensuring your business is covered, and your employees are protected.

A three-in-one service: HAVS, acoustics, and health checks

Avery Weigh-Tronix’ specialist team of tool testers offers a comprehensive value-add service designed to offer an efficient all-round health check, acoustic check, and HAVS testing service. Using one service provider for all these essential tool health checks reduces tool downtime and keeps your teams working at full capacity.

Our service is provided on-site, either line side (on the shop floor), in our mobile testing unit, or in a designated testing area within your premises. Hand-held and hand-guided tools are tested for vibration issues and acoustic problems at the same time – with both results recorded on the certificate.

In addition, we provide a full tool health check and repair any faults straight away, followed by a full re-calibration if required.

Vibration and acoustic testing is best conducted annually, but for tool health checks too, a 3-6 month interval plan is best practice.

Get compliant, protect your team

Protecting employees from HAVS and ensuring no compensation claims are brought against your business is straightforward. Choose a reliable testing partner with a service designed to keep disruption to a minimum, and maintain an accurate paper trail containing up-to-date certificates for all tools, not just a cross-section. This will provide evidence of your due diligence to both employees and auditors.

For more information on our on-site testing services, or to book a free site demo, contact us today